Finishing Services

One of the most diverse service offerings in the industry

The Crown Process

Crown offers one of the most diverse service offering of metal finishing in the industry, including highly customized programs and processes designed for each project. Projects typically include PCP process control, PFMA and a PPAP approval process. The Crown team is highly experienced in helping customers source raw materials and parts for finishing and later for final delivery through the supply chain. When customers work with Crown, they typically go through a five-step process:

Program Management – Complete Parts Solutions

Crown can manage complete sourcing from part concept and protyping, to finished products, including design, manufacturing and metal finishing.

Crown even sources raw materials domestically and internationally, while helping customers manage vendors, subcontractors, shipping and supply-chain logistics worldwide. In many ways, Crown operates like a tier-1 supplier with complete sourcing, finishing and JIT warehousing. Crown maintains extensive partnerships with a wide range of fabricators, including:

- Stampers

- Welders

- Extruders

- Casting plants

- Billet machining

- Forging mills

Buffing

Crown has developed one of the most advanced and high-volume buffing production lines in the industry. Crown is capable of buffing 50,000 parts per week. The lines are highly automated to ensure high-level efficiency, consistency and quality.

Robotic buffing not only increases speed and lowers costs, but the process has been developed to apply precise pressures to each part for maximum consistency – often in ways labor-intensive hand buffing cannot. For detailed applications that require manual buffing, Crown’s 40-plus highly experienced technicians are some of the best in the industry.

Polishing

Over the years Crown technicians and machine operators have met the challenges for finishing metal parts through integrating hand and robotic polishing procedures. With our custom designed automated work centers, we can apply precise levels of pressure at specific RPMs at each station to create a highly consistent, desired finish.

The planning process often is a close collaboration of customer OEM engineers and Crown engineers, through a highly transparent approach. Because Crown can polish more than 60,000 parts per day, the planning process is critical to ensure the best possible outcomes and consistency.

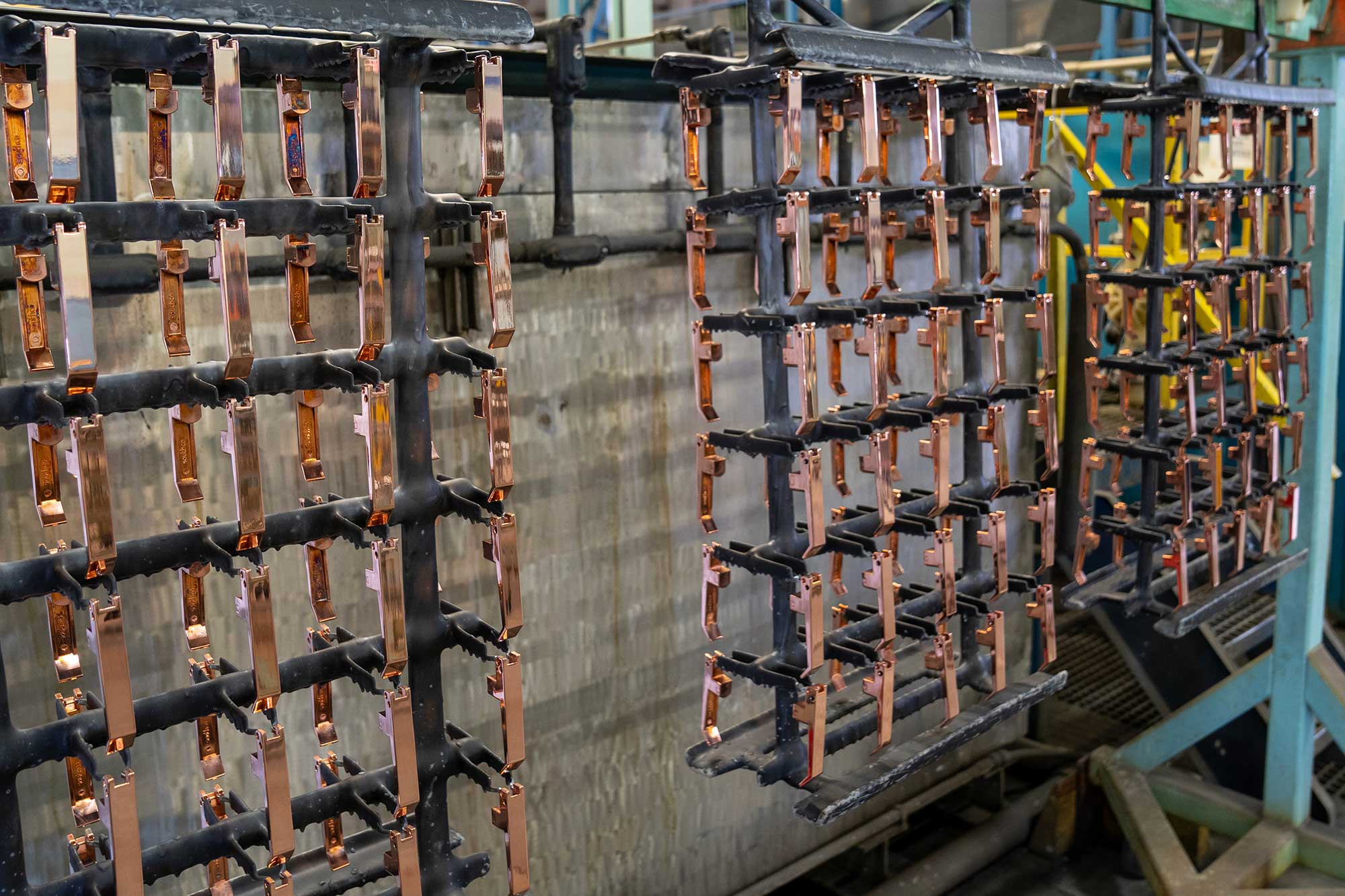

Plating

Crown maintains high-capacity, environmentally certified, automated plating lines capable of running more than 60,000 parts per day. Plating capabilities include hexavalent, trivalent, black chrome, nickel, tin, brass, aluminum and copper plating. Crown is one of the few metal finishing facilities in the nation authorized by automotive OEMs to perform black chrome plating.

Black Chrome Plating

As one of the few metal finishing facilities in the nation certified by automotive OEMs to perform black chrome plating, Crown’s process meets the strict testing standards for a sophisticated and unique look.

Tin Plating

Tin plating is a process Crown offers where a thin layer of tin is electroplated onto a metal surface to enhance corrosion resistance, improve solderability, and provide a smooth, shiny finish. This coating is commonly used in electronics, food packaging, and other applications where a non-toxic, protective barrier is essential.

Inspection

Crown maintains a high-capacity liquid penetrant inspection process on a monorail system to identify stress points and voids from the manufacturing process. All inspection processing is finalized with each customer before projects begin.

Product Marking

Often as part of a larger process, Crown can ink and etch a wide range of products and materials – all with custom specifications, including production markings, LPI identification, logos and branding for a variety of products, including truck wheels.

Liquid Coating, Powder Coating and Clear Coating

Areway engineers create specialized coatings for automotive parts designed to resist heat and wear, protect the metal and create cosmetic appearances few finishing facilities in the world can produce. Areway’s custom-designed automated line consists of 14 pre-treat stages, each with separate heating and environmentally safe cleaning solutions.

In-house chemists work with major coatings manufacturers to finalize each formula and ensure the most stringent operating specifications are met for each project. Masking templates are designed and developed in-house, then applied to parts before coating to enable contrasting colors.

Our partners benefit from powder coating their equipment because it provides superior protection against corrosion, chipping, and wear compared to traditional paint. It also offers an attractive, uniform appearance with a wide range of color options. Additionally, powder coating is environmentally friendly, as it produces less waste and contains no harmful solvents.

In the initial stages of the coatings line, parts are heated, rinsed and heated again with acid. The line moves to further rinsing, conversion coats, extensive surface prep and micro-etching. A sealant is applied, and the parts move to the dry-off oven, then to an automated paint booth and finally to cure ovens. All the steps are monitored and recorded through a central quality-control station.

Areway has spent decades refining a process that is virtually unmatched in the industry, while managing some of the largest projects for automotive parts in the. Areway’s customers span North America, Europe and Asia.

Powered by

Powered by