Metal finishing is not just an art; it’s also a science that relies on precise chemical processes to transform the surface of metals. Understanding the chemistry behind these techniques is crucial for achieving the desired results. We are going to delve into the science behind common metal finishing processes, detailing the chemicals involved, the step-by-step processes, and the impact on time, labor and materials.

Plating Process

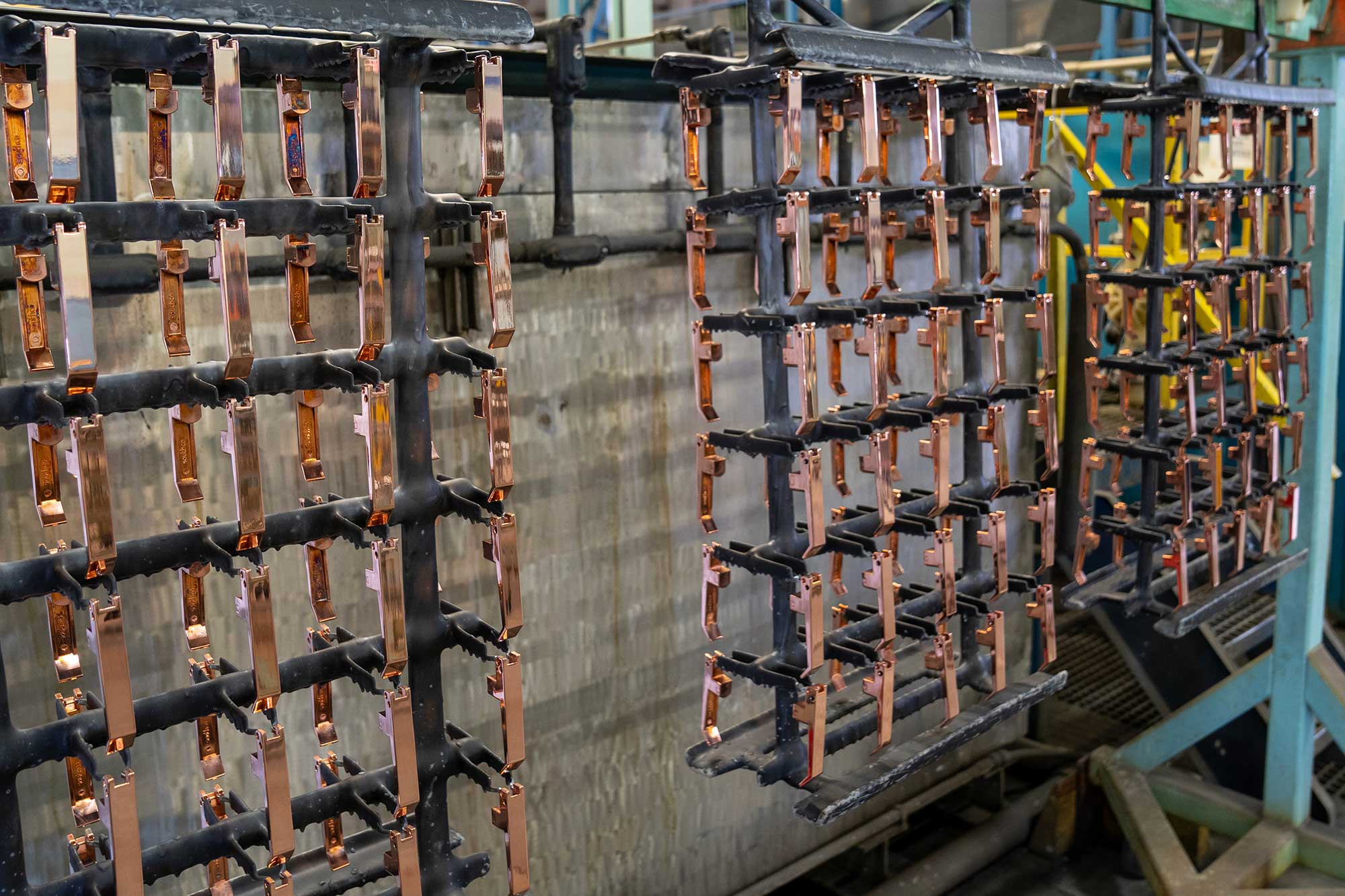

Chemistry: Plating involves the deposition of a layer of metal onto the base material. Common plating metals include chromium, nickel and gold. The process relies on electrochemistry, where metal ions in a solution are reduced and form a solid metal layer on the substrate.

Process:

- Cleaning: The metal surface is thoroughly cleaned to remove contaminants, oils and oxides.

- Electrolytic bath: The substrate is immersed in an electrolytic bath containing metal ions.

- Electroplating: A direct current is applied, causing metal ions to deposit onto the substrate, forming a metal layer.

- Post-treatment: The plated part may undergo further processes like polishing, buffing or passivation for enhanced finish and durability.

Impact: Plating can be time-consuming due to multiple steps and the need for precise control of bath conditions. It often requires skilled labor and can be costly due to the use of precious metals.

Anodizing Process

Chemistry: Anodizing is an electrolytic process primarily used for aluminum. It involves the formation of a protective oxide layer on the metal’s surface. The aluminum substrate becomes the anode in an electrolytic cell.

Process:

- Pre-cleaning: The aluminum is cleaned to remove impurities.

- Anodizing bath: The aluminum is immersed in an electrolytic bath typically containing sulfuric acid.

- Anodization: A direct current is applied, causing oxidation of the aluminum surface, forming an aluminum oxide layer.

- Coloring (optional): Dyes can be added to the process to achieve different colors.

- Sealing: The part is immersed in hot water or another sealing solution to close the pores in the oxide layer.

Impact: Anodizing is relatively fast and cost-effective compared to plating. It provides excellent corrosion resistance and durability but may require additional steps for coloring.

Powder Coating Process

Chemistry: Powder coating involves the application of a dry powder coating material that, when heated, forms a solid, durable and attractive finish. The coating material is typically a thermosetting polymer.

Process:

- Surface preparation: The metal surface is cleaned to remove contaminants and oils.

- Application: The dry powder coating is electrostatically applied to the substrate.

- Curing: The coated part is baked in an oven, allowing the powder to melt, flow and cure into a smooth, even finish.

Impact: Powder coating is relatively efficient, as it generates minimal waste and has a shorter processing time compared to plating. It requires less labor for application but necessitates an oven for curing.

Electropolishing Process

Chemistry: Electropolishing is an electrochemical process that removes a thin layer of material from the metal’s surface, resulting in a smooth, reflective finish. It primarily applies to stainless steel.

Process:

- Cleaning: The stainless steel is cleaned to remove contaminants.

- Immersion: The part is immersed in an electropolishing solution containing phosphoric acid and other chemicals.

- Electropolishing: A direct current is applied, causing the dissolution of surface imperfections and the formation of a polished layer.

- Neutralization and rinsing: The part is neutralized and thoroughly rinsed to remove any remaining chemicals.

Impact: Electropolishing enhances corrosion resistance and cleanliness. It requires careful control of bath conditions, making it labor-intensive and potentially time-consuming.

Passivation Process

Chemistry: Passivation is a chemical process used primarily with stainless steel to remove contaminants and enhance corrosion resistance. It typically involves nitric or citric acid.

Process:

- Cleaning: The stainless steel is cleaned to remove oils, grease and contaminants.

- Passivation bath: The part is immersed in a passivation bath containing acid.

- Reaction: The acid removes surface iron and contaminants, leaving behind a passive, corrosion-resistant layer.

- Rinsing and drying: The part is rinsed thoroughly and dried to remove any remaining acid and water.

Impact: Passivation is a relatively quick process, but it requires precision in acid concentration and bath conditions. It improves the corrosion resistance of stainless steel.

In conclusion, each metal finishing technique involves specific chemical processes that impact the time, labor and materials required. The choice of method depends on factors like the type of metal, desired finish and the specific project requirements. Understanding the science behind metal finishing is crucial for achieving the desired results and ensuring the longevity of metal surfaces.

Powered by

Powered by