In the aerospace and automotive industries, precision, performance and durability are paramount. Metal finishing plays a crucial role in enhancing these aspects while also ensuring safety and reliability. Let’s dive into the key applications of metal finishing in these industries, exploring the specific benefits it offers in various fields and applications.

Aerospace Industry

Commercial Aviation

Aircraft Exteriors: The exterior of commercial aircraft faces extreme environmental conditions, from high-altitude exposure to fluctuating temperatures. Metal finishing, such as anodizing and chemical conversion coating, is applied to aluminum components, ensuring resistance to corrosion and improving paint adhesion. This extends the lifespan of aircraft exteriors, reducing maintenance costs.

Aircraft Interiors: In the cabin, metal finishing techniques like electropolishing and passivation are applied to stainless steel components such as galley equipment, seating, and lavatories. These processes provide a smooth, easy-to-clean surface that meets stringent hygiene and safety standards, essential for passenger well-being.

Military and Defense

Aircraft Armor: In military aviation, armored aircraft components require specialized metal finishing, including hard anodizing and composite coatings. These finishes enhance structural integrity, ballistic resistance and stealth capabilities, crucial for military aircraft operating in high-risk environments.

Missiles and Munitions: Precision and reliability are critical in missile and munition systems. Metal finishing techniques like zinc plating and powder coating provide corrosion resistance and protect these systems during storage and transportation, ensuring they perform flawlessly when deployed.

Space Exploration

Spacecraft Components: For space travel, where equipment faces extreme conditions such as vacuum, radiation, and extreme temperature variations, metal finishing is essential. Coatings like thermal spray and chemical vapor deposition are applied to spacecraft components to enhance thermal insulation, radiation resistance, and overall durability.

Automotive Industry

Racing and High-Performance Vehicles

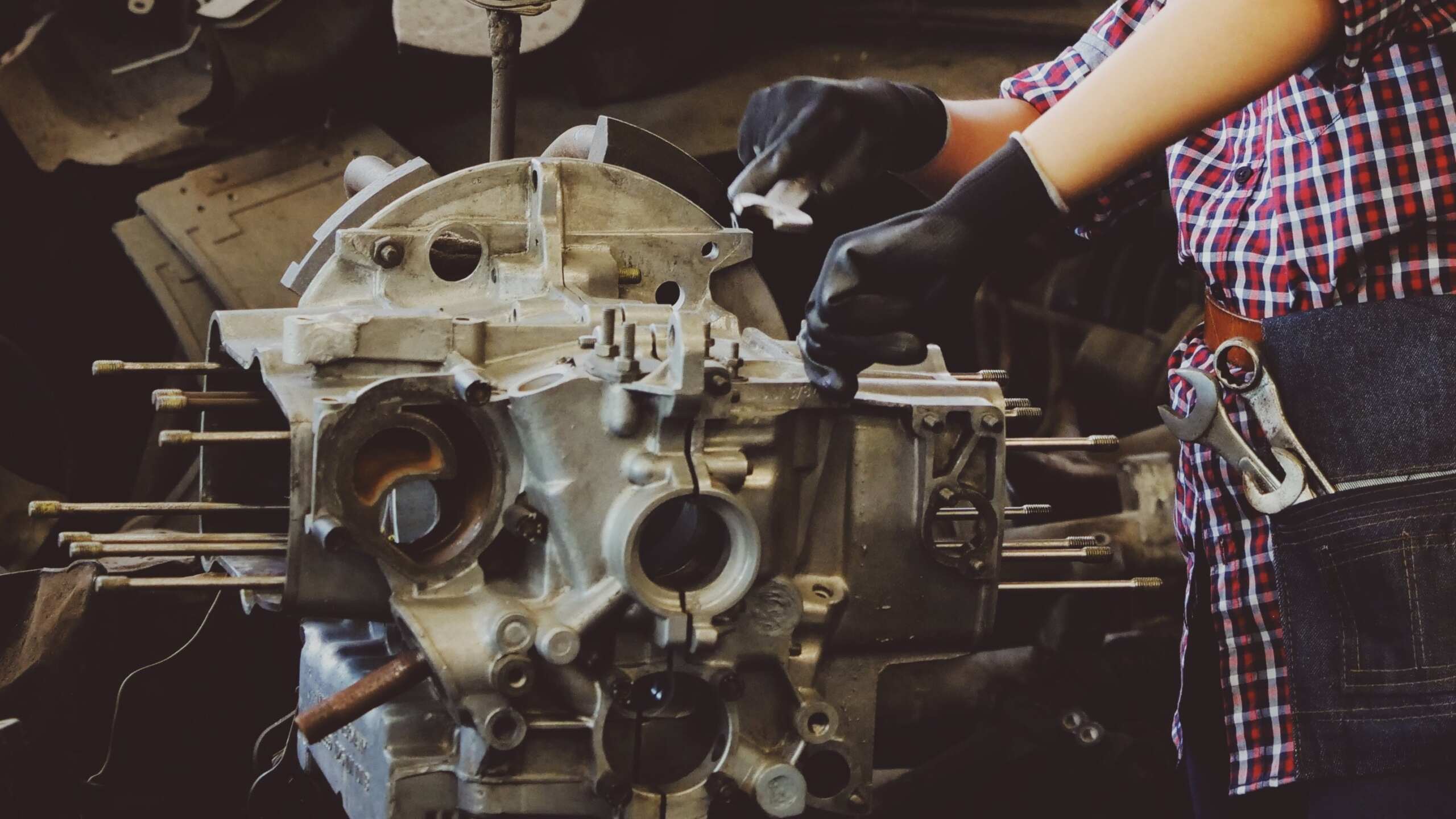

Engine Components: In high-performance engines used in racing and sports cars, metal finishing on critical components like pistons, cylinder heads and exhaust systems is crucial. Techniques like shot peening and nitriding improve strength, heat resistance and wear resistance, allowing engines to operate at peak performance under extreme conditions.

Shot peening works as a cold mechanical impact treatment accomplished by striking a ductile metallic surface with multiple high-velocity shots. Nitriding is a thermochemical process in which the surface of a ferrous metal, such as steel, is enriched with nitrogen.

Chassis and Suspension: In racing, where precise handling and control are vital, components like suspension parts and chassis components benefit from metal finishing techniques like electroplating and powder coating. These finishes enhance corrosion resistance, durability and overall performance.

Commercial and Heavy-Duty Vehicles

Trucking Industry: In the trucking industry, where long-haul vehicles face extended exposure to the elements and road chemicals, metal finishing on critical components such as frames, suspension systems, and cargo containers is essential. Powder coating and zinc-nickel plating offer excellent corrosion protection, extending the lifespan of these vehicles.

Electric Vehicles (EVs): As EVs become more prevalent, battery housings and electrical components require specialized metal finishing. Coatings like nickel-plating and conductive coatings ensure corrosion resistance and proper electrical conductivity, contributing to the reliability and efficiency of EVs.

Consumer Automotive

Automotive Exteriors: In consumer vehicles, metal finishing techniques like clear coating and powder coating are applied to exterior components like wheels, bumpers, and trim. These finishes provide corrosion resistance and enhance the aesthetics of vehicles, maintaining their appearance and value.

Interior Components: Inside the cabin, metal finishing is applied to components like door handles, knobs, and trim. Finishes like electroplating and anodizing not only improve appearance but also provide durability and resistance to wear and tear, ensuring a premium driving experience.

In both the aerospace and automotive industries, the choice of metal finishing techniques and applications depends on the specific requirements of each sector. Whether it’s enhancing the durability of aircraft components or optimizing the performance of high-performance vehicles, metal finishing plays a pivotal role in ensuring safety, longevity and reliability in these critical sectors of transportation and technology.

Powered by

Powered by